Batch mixers are industrial mixers that work with a load of a single material per time before they are filled with another. The batch mixers can mix a wide range of products, from fine powders to heavy and dense powders, including cement. Read More…

As a world leader in industrial mixer manufacturing, KADY International offers high-performance industrial mixing machinery including top and bottom entry batch mixers, high shear mixers and chemical mixers.

Frain Industries is the world’s largest provider of high quality processing machinery! We offer a wide variety of mixers based on the product and volume our customers require.

Ross is a manufacturer of industrial mixing, blending and dispersion equipment since 1842. We offer sanitary, standard and custom equipment designed to meet the varied mixing requirements of our customers from virtually all the process industries. Our plants in the United States, China and India are all fully equipped with advanced engineering and production tools. In the US alone, we operate ...

Admix, Inc. manufactures stainless steel mixing technologies & assists with tough mixing issues for a variety of markets. Choose from products such as basic mixers, Rotomaxx™ high torque mixers, BenchMix™ programmable lab mixers and more.

PerMix has been manufacturing mixing and blending equipment since 1954 for the pharmaceutical, nutraceutical, cosmeceutical, food, and chemical industry. PerMix leads the industry in innovative, performance driven, Value Added Engineering mixing solutions of all types for all industries. With over 28 types of mixers, we lead the industry in mixing solutions when it comes to mixing powders,...

At Akona Process Solutions, we dedicate ourselves to designing and building mixers that deliver consistent performance and long-lasting value. We understand that reliable mixing technology is the foundation of countless operations, so we engineer our mixers with precision, durability, and adaptability in mind.

Our high-performance mixers ensure efficient and consistent material blending across a wide range of industries. Designed to handle everything from fine powders to coarse aggregates, with or without liquid addition, they deliver uniformity and precision in every batch. With innovative engineering, optimized flow patterns, and reduced energy consumption, they enhance productivity while minimizing...

Are you searching for industrial mixers? Your search is done and we supply the best quality industrial mixers on the market. We take pride in our manufacturing but also in our customer service. We are more than just a supplier; we desire a long lasting business relationship which results in years of customer satisfaction. Your experience is important to us. For all of your mixing needs visit our...

At ARDE Barinco, our goal is to help our clients mix, disperse, deagglomerate, grind and compound their high quality products in the shortest amount of time with the lowest operating and capital cost. Complete, up to date pricing for all standard mixers and spare parts is shown on our website.

More Batch Mixer Manufacturers

What is a Batch Mixer?

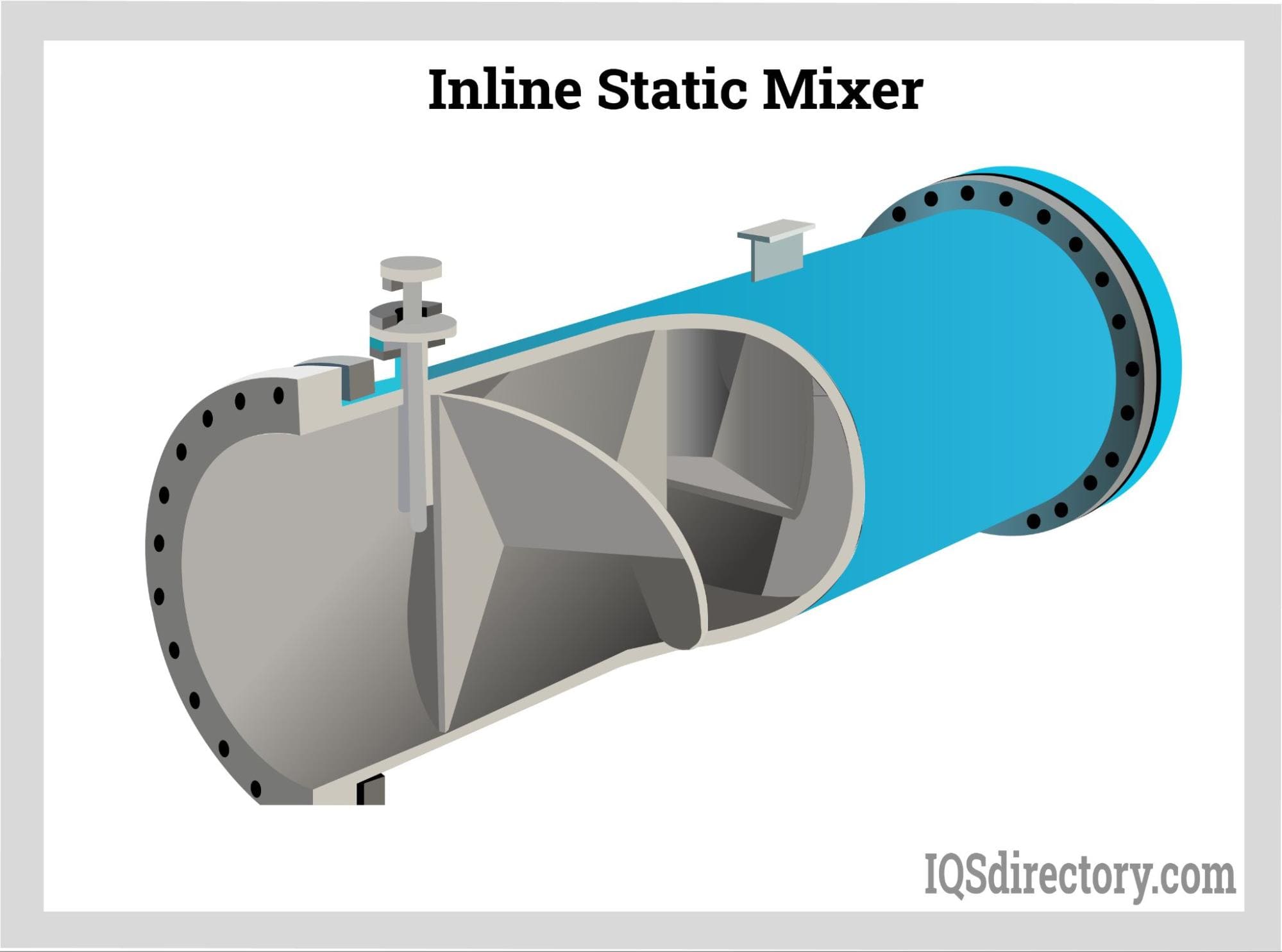

Because any mixer can work in batches, there is no single mixer that can automatically be said to be a batch mixer. Continuously fed mixers can be placed in a production line to carry materials and products through an automated system.

Batch mixers can also be part of a production line, but the line would need to be brought to a standstill as the mixer completes one batch at a time.

Some of the materials used for batch mixers include beverages, medicines, glue, toothpaste, and petroleum products. In addition, batch mixers can produce cement slurries of consistent densities.

How Batch Mixers Function

This batch mixing process typically consists of three sequential steps. These steps are weighing and loading the mix components, mixing, and discharging the mixed product.

First, all the contained ingredients are mixed and loaded into the batch mixer. They are then mixed for a certain duration. In a batch mixer, the retention time is usually reached based on the time required to achieve the desired level of homogeneity in the product.

The mixing cycle can range from a few seconds, with included high-intensity periods, to a few hours. The product can also be additionally processed through heating or cooling. The resulting mix obtained from the complete batch mixing process is then discharged from the mixing vessel. This mixer discharge can be rapid, or it may endure subsequent time if the mixer is used as a surge vessel to feed a downstream process.

A mixer is not ideal for storage because this can create a bottleneck in the process. A mixer cannot store and mix different products concurrently.

Types of Batch Mixers

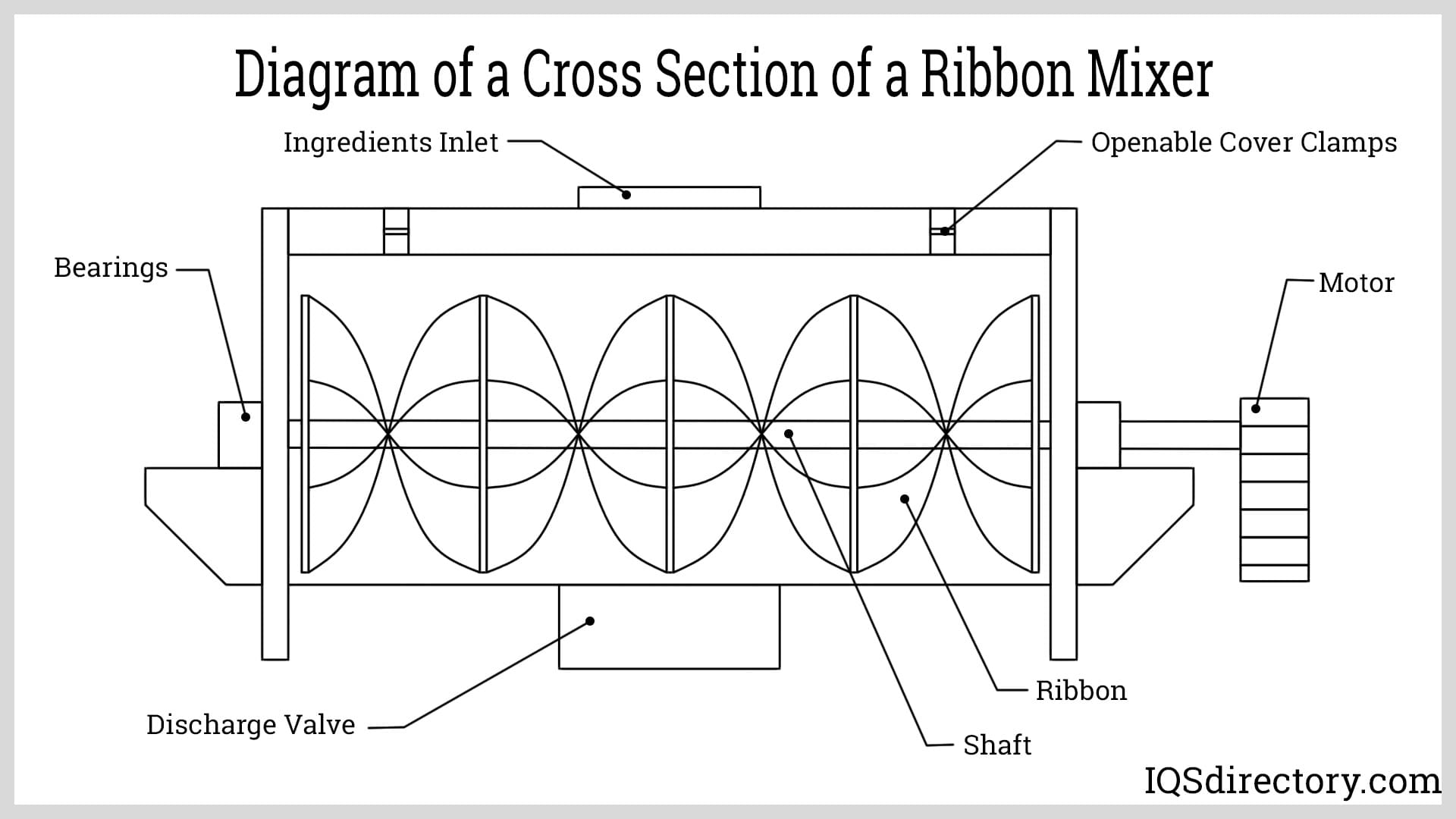

Types of batch mixers include high shear mixers, agitators, ribbon blenders, vacuum blenders and mixers, and paddle mixers.

High Shear Mixers

High shear mixers are mixers used in industries to utilize countercurrent mixing, which subjects substances to strong parallel forces. During this countercurrent mixing process, the mixing pan and the tools used for mixing revolve rapidly in opposite directions, resulting in the uniformity of the substance.

Agitators

Agitators are a type of batch mixer for low shear applications. They are powered by impellers to mix substances with low viscosities. The agitators have a wide range of sizes, from small agitators used in laboratories to large industrial agitators with capacities of 10,000 gallons.

Vacuum Mixers

This type of batch mixer can have either a horizontal or vertical construction. Vacuum mixers use a combination of low internal heat and vacuum pressure. This combination aims to blend the mixture while also removing the contained moisture.

Applications and Uses of Batch Mixers

Batch mixers can produce cement slurries of consistent densities, so they are widely used in cementing services. Other areas where batch mixers are significant include food processing, cosmetics, toiletry, pharmaceuticals, chemicals, the pulp and paper sector, agriculture, automotives, and industries that deal with adhesives and sealants.

Choosing the Correct Batch Mixer Manufacturer

To ensure you have the most productive outcome when purchasing a batch mixer from a batch mixer manufacturer, it is important to compare several companies using our directory of batch mixer manufacturers. Each batch mixer manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each batch mixer business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple batch mixer companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services