De Dietrich Process Systems

De Dietrich Process SystemsRequest A Quote

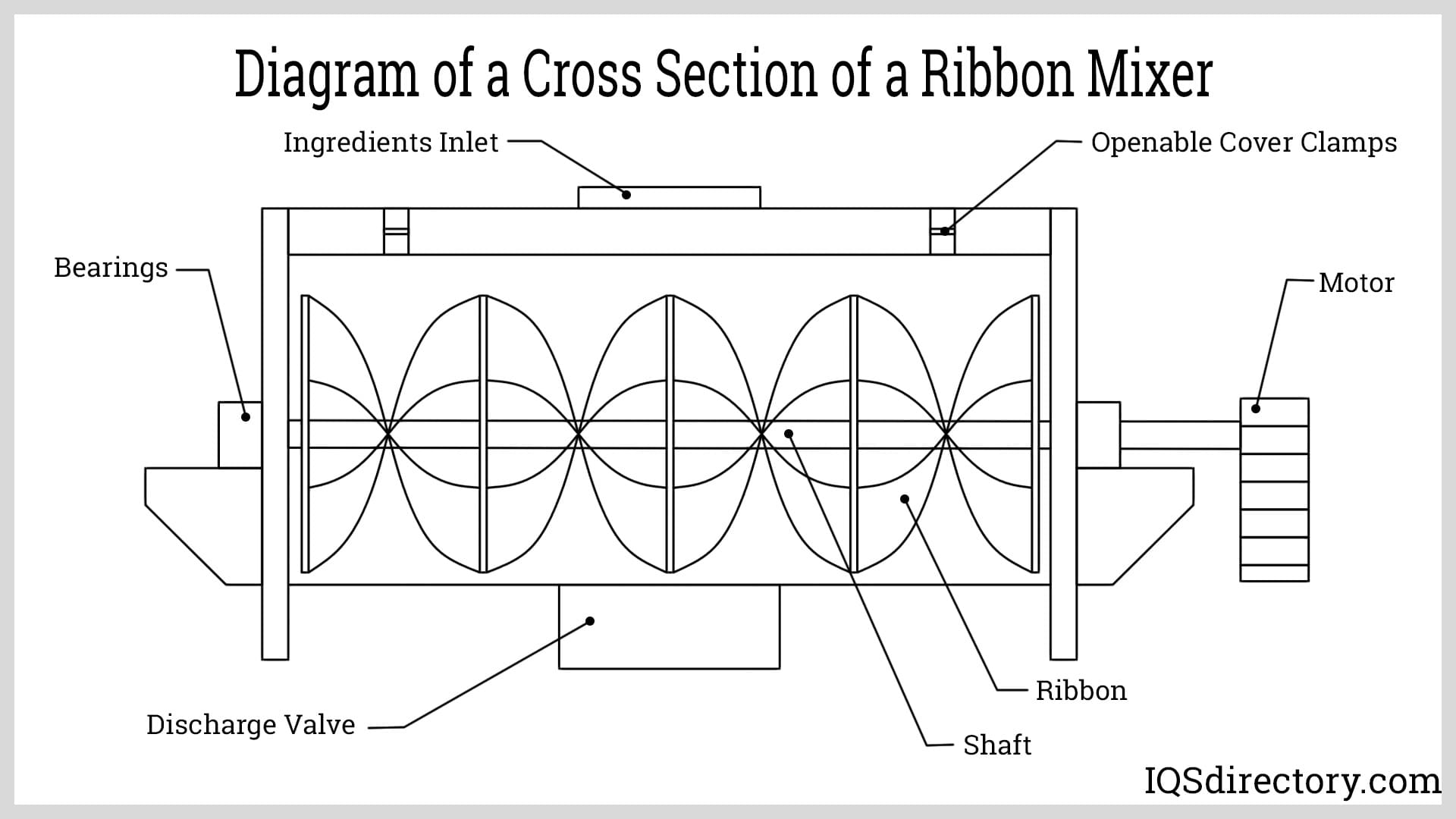

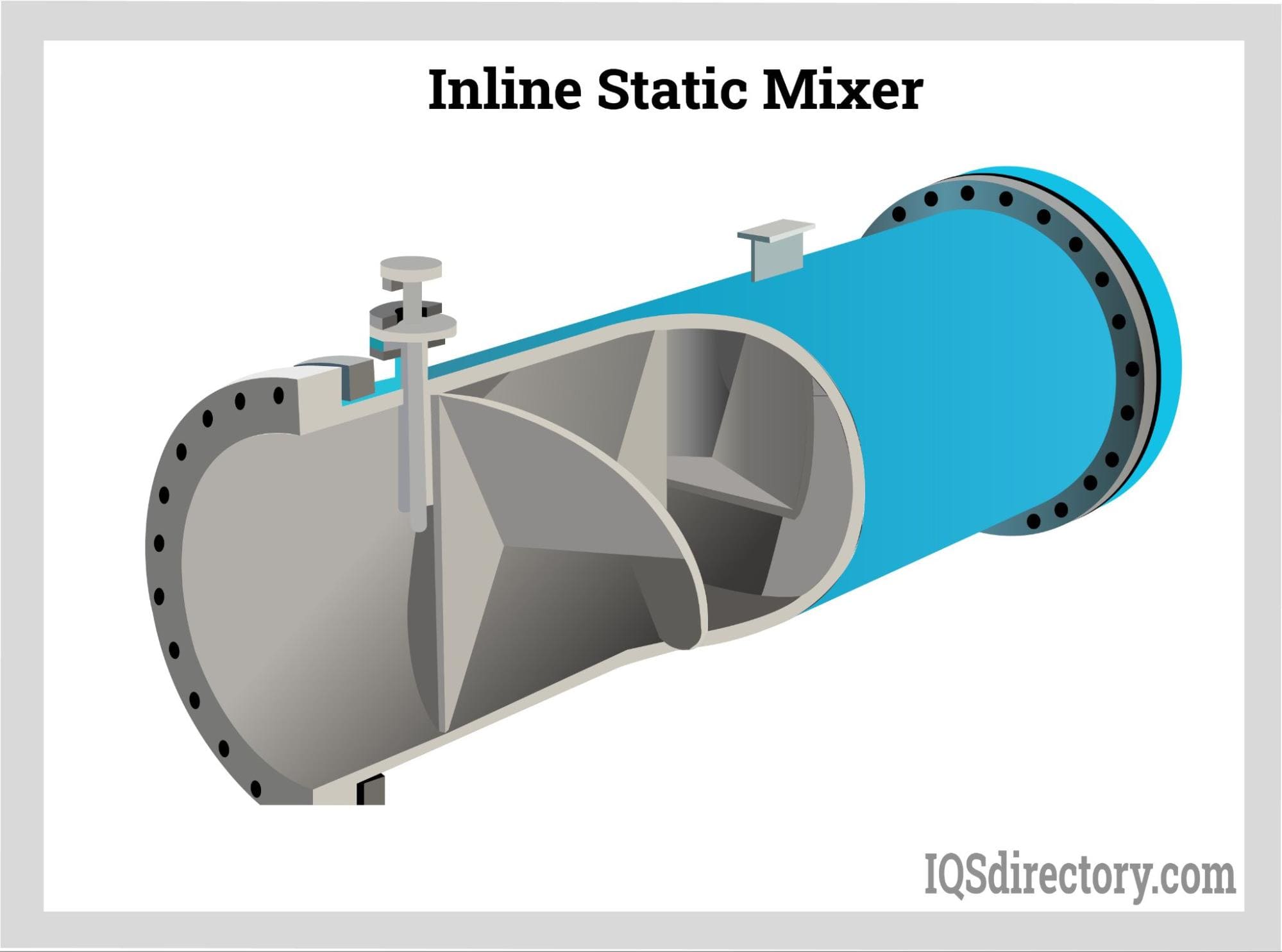

Mountainside, NJDe Dietrich Process Systems is committed to delivering exceptional mixing solutions tailored to the unique needs of its customers. The company's portfolio includes a wide variety of industrial mixers designed for applications across multiple industries, including pharmaceuticals, chemicals, food and beverages, cosmetics, and more. Their mixers are engineered to meet the most demanding requirements, whether it be for blending, emulsifying, dispersing, or homogenizing. With a focus on precision and consistency, De Dietrich Process Systems' mixers can handle a broad range of viscosities, temperatures, and shear levels. The company takes great pride in its diverse range of mixer types and configurations. De Dietrich Process Systems offers an array of innovative mixing technologies such as glass-lined, stainless steel, and high-performance polymer mixers. Their product line includes agitated vessels, paddle mixers, ribbon blenders, high-shear mixers, and vacuum mixers, among others. Each mixer is manufactured to the highest industry standards, ensuring optimal performance, durability, and safety. De Dietrich Process Systems not only provides top-of-the-line mixing equipment but also offers a comprehensive suite of services to support its customers throughout the entire lifecycle of their mixers. From initial process analysis and equipment selection to installation, start-up, and training, the company's dedicated team of experts ensures seamless integration and optimal performance of the mixers within customers' operations. They provide hands-on training programs to empower clients with the necessary knowledge to operate and maintain their equipment effectively. De Dietrich Process Systems' commitment to customer satisfaction extends to its comprehensive after-sales services. Their global network of service centers and highly skilled technicians offer preventive maintenance, troubleshooting, repairs, and spare parts supply, ensuring uninterrupted operation and minimizing downtime. With a strong focus on customer-centric support, De Dietrich Process Systems aims to build long-term partnerships with its clients, providing them with reliable assistance and technical expertise whenever needed. Innovation is at the core of De Dietrich Process Systems' business philosophy. The company continuously invests in research and development to stay at the forefront of mixing technologies. By collaborating with industry leaders and leveraging advanced engineering practices, De Dietrich Process Systems brings cutting-edge solutions to its customers, allowing them to enhance productivity, efficiency, and product quality. De Dietrich Process Systems' reputation for excellence and dedication to customer satisfaction has earned them a global presence, serving customers in various industries and regions worldwide. Their commitment to quality, reliability, and innovation has made them a trusted partner for businesses of all sizes, from small-scale enterprises to multinational corporations. De Dietrich Process Systems is a leading provider of industrial mixing solutions, offering a diverse range of high-quality mixers and comprehensive services. With a focus on precision, efficiency, and customer satisfaction, the company strives to deliver tailored solutions that meet the specific mixing requirements of various industries. Through their innovative products and unwavering commitment to service excellence, De Dietrich Process Systems empowers its customers to optimize their mixing processes and achieve superior results.

Leading Industrial Mixer Manufacturers

More Industrial Mixer Manufacturers

Additional Categories: Electric Coils, Electric Transformers

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services