Mixing and blending are critical processes in the manufacturing or processing of materials, ranging from food and beverage products to paints and coatings. Dispersers and mixers are both essential types of equipment used in these processes, but they differ in their specific functions and design. Mixers are used to combine and blend different components, such as liquids, powders, and gasses, into a homogenous mixture. Dispersers, on the other hand, are specifically designed to disperse and break down particles, such as solids or liquids, into smaller particles and distribute them evenly throughout a liquid medium. Read More…

As a world leader in industrial mixer manufacturing, KADY International offers high-performance industrial mixing machinery including top and bottom entry batch mixers, high shear mixers and chemical mixers.

Frain Industries is the world’s largest provider of high quality processing machinery! We offer a wide variety of mixers based on the product and volume our customers require.

Ross is a manufacturer of industrial mixing, blending and dispersion equipment since 1842. We offer sanitary, standard and custom equipment designed to meet the varied mixing requirements of our customers from virtually all the process industries. Our plants in the United States, China and India are all fully equipped with advanced engineering and production tools. In the US alone, we operate ...

Admix, Inc. manufactures stainless steel mixing technologies & assists with tough mixing issues for a variety of markets. Choose from products such as basic mixers, Rotomaxx™ high torque mixers, BenchMix™ programmable lab mixers and more.

PerMix has been manufacturing mixing and blending equipment since 1954 for the pharmaceutical, nutraceutical, cosmeceutical, food, and chemical industry. PerMix leads the industry in innovative, performance driven, Value Added Engineering mixing solutions of all types for all industries. With over 28 types of mixers, we lead the industry in mixing solutions when it comes to mixing powders,...

At Akona Process Solutions, we dedicate ourselves to designing and building mixers that deliver consistent performance and long-lasting value. We understand that reliable mixing technology is the foundation of countless operations, so we engineer our mixers with precision, durability, and adaptability in mind.

Our high-performance mixers ensure efficient and consistent material blending across a wide range of industries. Designed to handle everything from fine powders to coarse aggregates, with or without liquid addition, they deliver uniformity and precision in every batch. With innovative engineering, optimized flow patterns, and reduced energy consumption, they enhance productivity while minimizing...

Are you searching for industrial mixers? Your search is done and we supply the best quality industrial mixers on the market. We take pride in our manufacturing but also in our customer service. We are more than just a supplier; we desire a long lasting business relationship which results in years of customer satisfaction. Your experience is important to us. For all of your mixing needs visit our...

At ARDE Barinco, our goal is to help our clients mix, disperse, deagglomerate, grind and compound their high quality products in the shortest amount of time with the lowest operating and capital cost. Complete, up to date pricing for all standard mixers and spare parts is shown on our website.

More Disperser Manufacturers

Components of Dispersers

Dispersers have several common components that work together to break apart solid particles or agglomerates and disperse them evenly in a liquid medium. These components include:

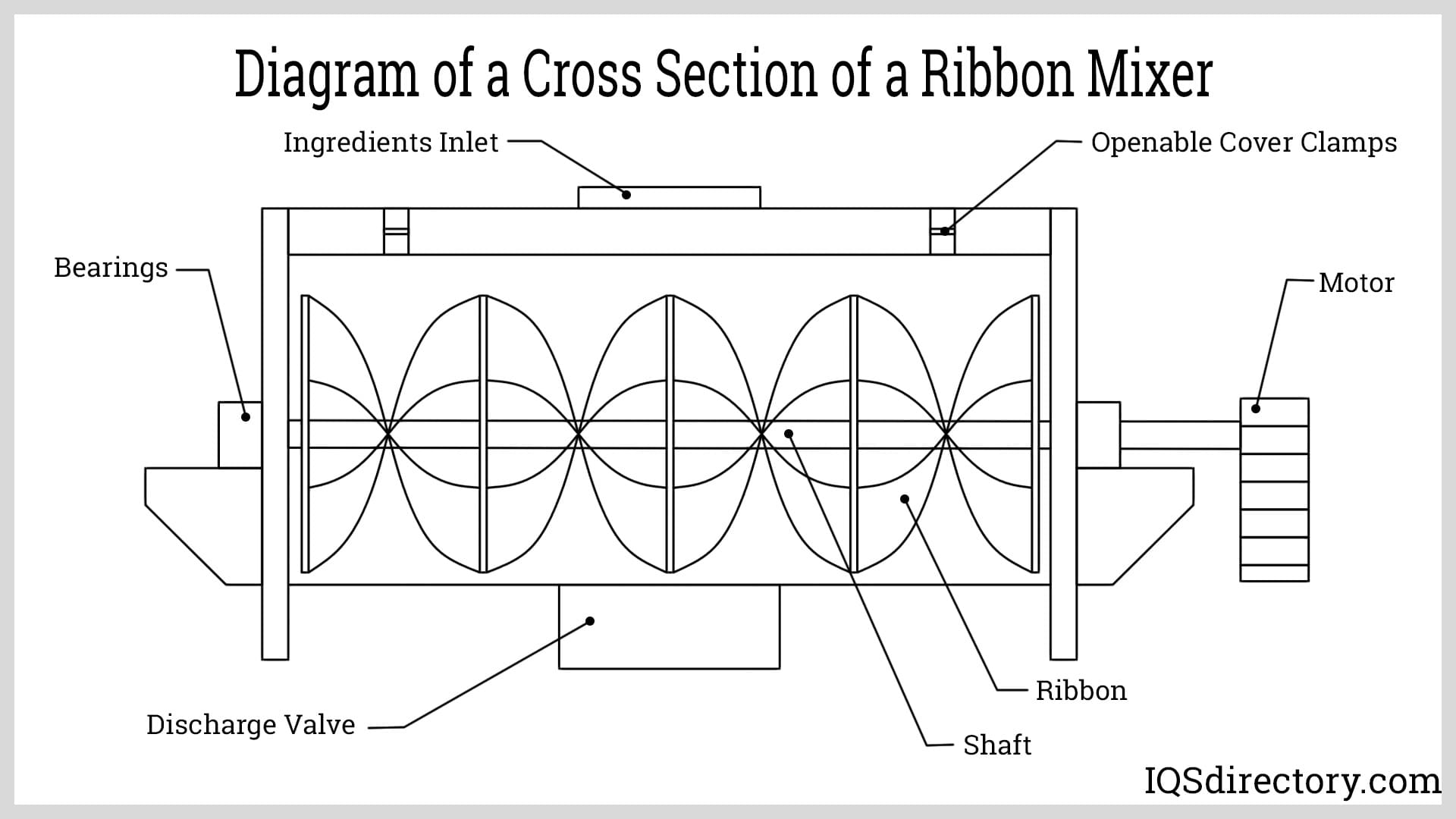

Motor

This component provides the power to drive the blades or rotors that disperse the particles.

Shaft

The shaft connects the motor to the impeller, which is the blade or rotor that creates the dispersing action.

Impeller

The impeller is the rotating component of the disperser that creates high shear forces and breaks apart agglomerates into smaller particles.

Vessel or Tank

The vessel or tank contains the liquid medium and the particles to be dispersed.

When the motor is activated, the impeller rotates at high speeds, creating high shear forces that break apart any agglomerates or particles in the liquid medium. The broken particles are then distributed evenly in the liquid medium, resulting in a stable and consistent dispersion.

Types of Dispersers

There are several types of dispersers that are used in different applications, depending on the type of material being dispersed and the desired dispersion quality. Here are some of the most common types of dispersers:

High-Speed Dispersers

These are the most commonly used dispersers and are designed to handle a wide range of viscosities and particle sizes. They typically have a vertical shaft and a single impeller that creates a strong vortex and high shear forces.

Multi-Shaft Dispersers

These are similar to high-speed dispersers, but they have multiple impellers on a single shaft or multiple shafts. They are used for more complex or viscous formulations that require more intensive mixing.

Bead Mills

These dispersers use small glass or ceramic beads instead of blades to create high shear forces and break apart particles. They are often used for fine particle size reduction and high-quality dispersion of pigments or other materials.

Ultrasonic Dispersers

These use high-frequency sound waves to create cavitation bubbles that break apart particles. They are used for delicate or heat-sensitive materials that may be damaged by traditional dispersing methods.

Considerations Regarding Dispersers

There are some issues to consider regarding dispersers that can affect their performance and effectiveness in certain applications. For example, the high shear forces generated by dispersers can cause excessive heat buildup in the liquid medium, which can affect the stability or quality of the dispersion. Additionally, dispersers may not be effective for materials that are highly viscous or have high levels of solids, as these materials may not be able to be dispersed evenly. Lastly, some types of dispersers may be more expensive or require more specialized maintenance than others, depending on the specific application.

Benefits of Dispersers

Despite their limitations, dispersers offer several benefits in the manufacturing or processing of materials. These benefits include:

Improved Product Quality

Dispersers can create more stable and consistent dispersions, resulting in higher-quality products with better color, texture, or performance.

Increased Efficiency

Dispersers can reduce processing time and energy consumption compared to other mixing methods, resulting in faster and more cost-effective production.

Greater Flexibility

Dispersers can handle a wide range of viscosities and particle sizes, making them versatile tools for various applications.

Customization

Dispersers can be customized to meet specific requirements, such as different impeller shapes or materials, to achieve desired dispersion characteristics.

Applications of Dispersers

As a result of these favorable traits, dispersers are widely used in many industries and applications, including:

Paints and Coatings

Dispersers are used to disperse pigments, fillers, and other additives in paint and coating formulations, resulting in a more stable and uniform product.

Pharmaceuticals

Dispersers are used to prepare suspensions, emulsions, and other formulations of drugs and other pharmaceutical products.

Food and Beverage

Dispersers are used to disperse and homogenize ingredients in food and beverage products, such as sauces, dressings, and dairy products.

Cosmetics

Dispersers are used to disperse pigments and other ingredients in cosmetics and personal care products, such as lotions, creams, and makeup.

Choosing the Proper Disperser Supplier

To ensure you have the most productive outcome when purchasing a disperser from a disperser supplier, it is important to compare several companies using our directory of disperser suppliers. Each disperser supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each disperser company website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple disperser businesses with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services