High speed mixers come in a variety of shapes and sizes, from small high speed lab mixers to factory-sized high speed mixers than can hold and mix hundreds of gallons of material at one time. These high speed mixers do not all have inner components that spin like a rotor mixer; some of them simple spin an entire container vertically or horizontally at high speeds to achieve the desired effect. Read More…

As a world leader in industrial mixer manufacturing, KADY International offers high-performance industrial mixing machinery including top and bottom entry batch mixers, high shear mixers and chemical mixers.

Frain Industries is the world’s largest provider of high quality processing machinery! We offer a wide variety of mixers based on the product and volume our customers require.

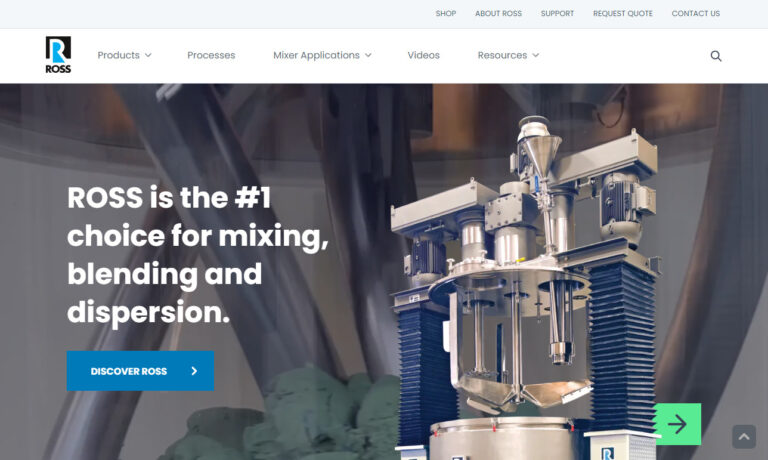

Ross manufactures the world’s broadest line of High Shear Mixers – from traditional High Speed Dispersers and single-stage Rotor/Stator Mixers to new generation ultra- high shear patented mixing technologies. Our high performance rotor/stator mixers are available in sizes from benchtop through full-scale production, in batch and in-line configurations, with a multitude of options to help...

Admix, Inc. manufactures stainless steel mixing technologies & assists with tough mixing issues for a variety of markets. Choose from products such as basic mixers, Rotomaxx™ high torque mixers, BenchMix™ programmable lab mixers and more.

PerMix has been manufacturing mixing and blending equipment since 1954 for the pharmaceutical, nutraceutical, cosmeceutical, food, and chemical industry. PerMix leads the industry in innovative, performance driven, Value Added Engineering mixing solutions of all types for all industries. With over 28 types of mixers, we lead the industry in mixing solutions when it comes to mixing powders,...

At Akona Process Solutions, we dedicate ourselves to designing and building mixers that deliver consistent performance and long-lasting value. We understand that reliable mixing technology is the foundation of countless operations, so we engineer our mixers with precision, durability, and adaptability in mind.

Our high-performance mixers ensure efficient and consistent material blending across a wide range of industries. Designed to handle everything from fine powders to coarse aggregates, with or without liquid addition, they deliver uniformity and precision in every batch. With innovative engineering, optimized flow patterns, and reduced energy consumption, they enhance productivity while minimizing...

Are you searching for industrial mixers? Your search is done and we supply the best quality industrial mixers on the market. We take pride in our manufacturing but also in our customer service. We are more than just a supplier; we desire a long lasting business relationship which results in years of customer satisfaction. Your experience is important to us. For all of your mixing needs visit our...

At ARDE Barinco, our goal is to help our clients mix, disperse, deagglomerate, grind and compound their high quality products in the shortest amount of time with the lowest operating and capital cost. Complete, up to date pricing for all standard mixers and spare parts is shown on our website.

More High Speed Mixer Manufacturers

In a lab setting, high speed mixers are used to process chemical or blood samples. These samples are obviously very small; usually just large enough to fill a test tube. They are placed in a high speed mixer that sits on top of a table or shelf. Batch mixers are typically much larger and they are operated by automated or manual controls in a warehouse or factory.

The high speeds that their large electric motor produce create enough velocity to achieve the necessary consistency in a mixture but it moves on to the next process or goes to a plant for packaging. High speed mixers save time because they work so efficiently, but they also allow for quality mixing that would be otherwise impossible.

Certain materials would not break down to the right size and texture for their final applications unless these extreme high speeds were achieved during their mixing.

Some specialized high speed mixers known as dual asymmetrical centrifugal force mixers are used in laboratory applications where air bubbles need to be eliminated from a substance. These machines spin an arm quickly in one direction, while a small container mounted on the arm that is full of the test substance spins at the same time in the opposite direction. No blades are necessary for this type of mixing, and the right balance in the substance can often be attained in just a few seconds.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services