A paddle mixer is a type of mixer utilized in mixing viscous or slurry liquids, solids, and wet-dry mixing. It consists of a central shaft axis that serves to hold the blades. These mixers are most often used in dry mixing but can also accommodate liquid-solid mixing. Read More…

As a world leader in industrial mixer manufacturing, KADY International offers high-performance industrial mixing machinery including top and bottom entry batch mixers, high shear mixers and chemical mixers.

Frain Industries is the world’s largest provider of high quality processing machinery! We offer a wide variety of mixers based on the product and volume our customers require.

Ross has built the most advanced blending equipment for over 170 years. Our Paddle Blenders and Ribbon Blenders are used in food, chemical, pharmaceutical, plastics, agriculture and other process industries. We have the world’s largest inventory of blenders. If we have a blender that meets your needs, we will ship it fast. If you need a custom design with features we don’t normally stock, ...

Admix, Inc. manufactures stainless steel mixing technologies & assists with tough mixing issues for a variety of markets. Choose from products such as basic mixers, Rotomaxx™ high torque mixers, BenchMix™ programmable lab mixers and more.

PerMix has been manufacturing mixing and blending equipment since 1954 for the pharmaceutical, nutraceutical, cosmeceutical, food, and chemical industry. PerMix leads the industry in innovative, performance driven, Value Added Engineering mixing solutions of all types for all industries. With over 28 types of mixers, we lead the industry in mixing solutions when it comes to mixing powders,...

At Akona Process Solutions, we dedicate ourselves to designing and building mixers that deliver consistent performance and long-lasting value. We understand that reliable mixing technology is the foundation of countless operations, so we engineer our mixers with precision, durability, and adaptability in mind.

Our high-performance mixers ensure efficient and consistent material blending across a wide range of industries. Designed to handle everything from fine powders to coarse aggregates, with or without liquid addition, they deliver uniformity and precision in every batch. With innovative engineering, optimized flow patterns, and reduced energy consumption, they enhance productivity while minimizing...

Are you searching for industrial mixers? Your search is done and we supply the best quality industrial mixers on the market. We take pride in our manufacturing but also in our customer service. We are more than just a supplier; we desire a long lasting business relationship which results in years of customer satisfaction. Your experience is important to us. For all of your mixing needs visit our...

At ARDE Barinco, our goal is to help our clients mix, disperse, deagglomerate, grind and compound their high quality products in the shortest amount of time with the lowest operating and capital cost. Complete, up to date pricing for all standard mixers and spare parts is shown on our website.

More Paddle Mixer Manufacturers

What is a Paddle Mixer?

A paddle mixer can mix pastes like mortar, drywall mud, and thin and thick-set liquids. The speed of paddle mixers is about half the RPM of most drills, but they typically have a higher torque to help them power large mixing bits and paddles through thick mud.

Paddle mixers are also known as mud mixers. They can be used as a stand-alone agglomeration device or as a mixing step in a large agglomeration process that uses an agglomeration drum or disc pelletizer.

How Paddle Mixers Work

Paddle mixers are similar to baking paddle mixers: their role is to add water to a powdered material like mortar. A mixing bit or paddle is installed in the paddle mixer, inserted into the mix, and spun until the desired consistency is reached.

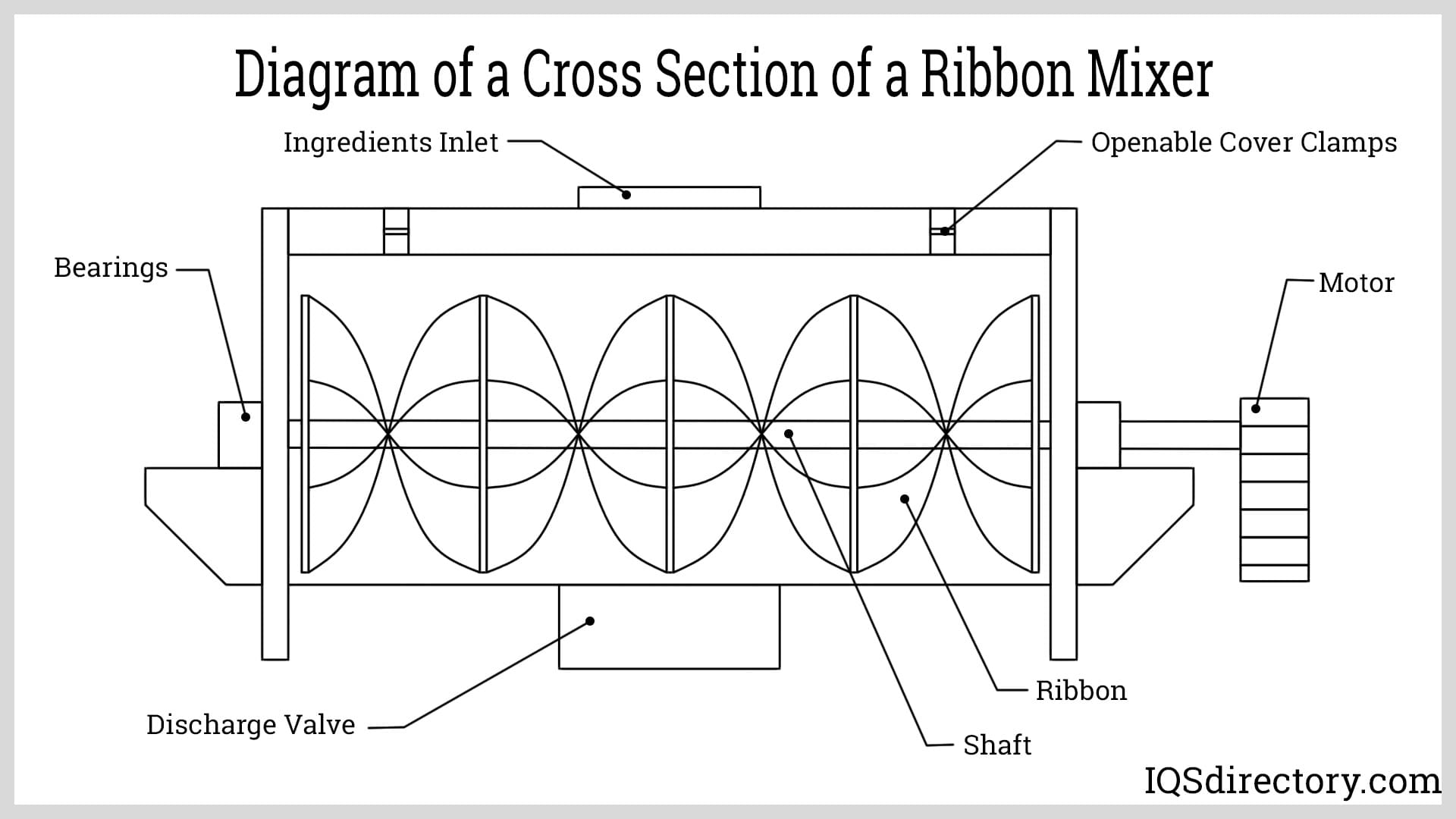

Paddle mixers use dual rotating shafts consisting of pitched paddles to create a folding and kneading-over motion inside the trough. Materials and binders can be continuously added to the mixer.

Materials are moved from the bottom of the trough, along the middle, and back down the sides by the pitched paddles to create a homogenous mixture.

Types of Paddle Mixers

The different types of paddle mixers include:

Batch Type Two Shaft Paddle Mixers

These paddle mixers can achieve high-quality mixtures in a very short mixing time at the lowest energy consumption possible. In addition, the product is handled gently and does not get damaged during the process.

These types of paddle mixers consist of two drums that are parallel, each having counter-rotating shafts equipped with paddles. The paddles promote a homogeneous mixture irrespective of the size or density of the particles, with counter-rotation of the paddles that overlap to bring added efficiency.

The design of batch type paddle mixers offers gentle and low shear forces, allowing a rapid mix at low energy consumption.

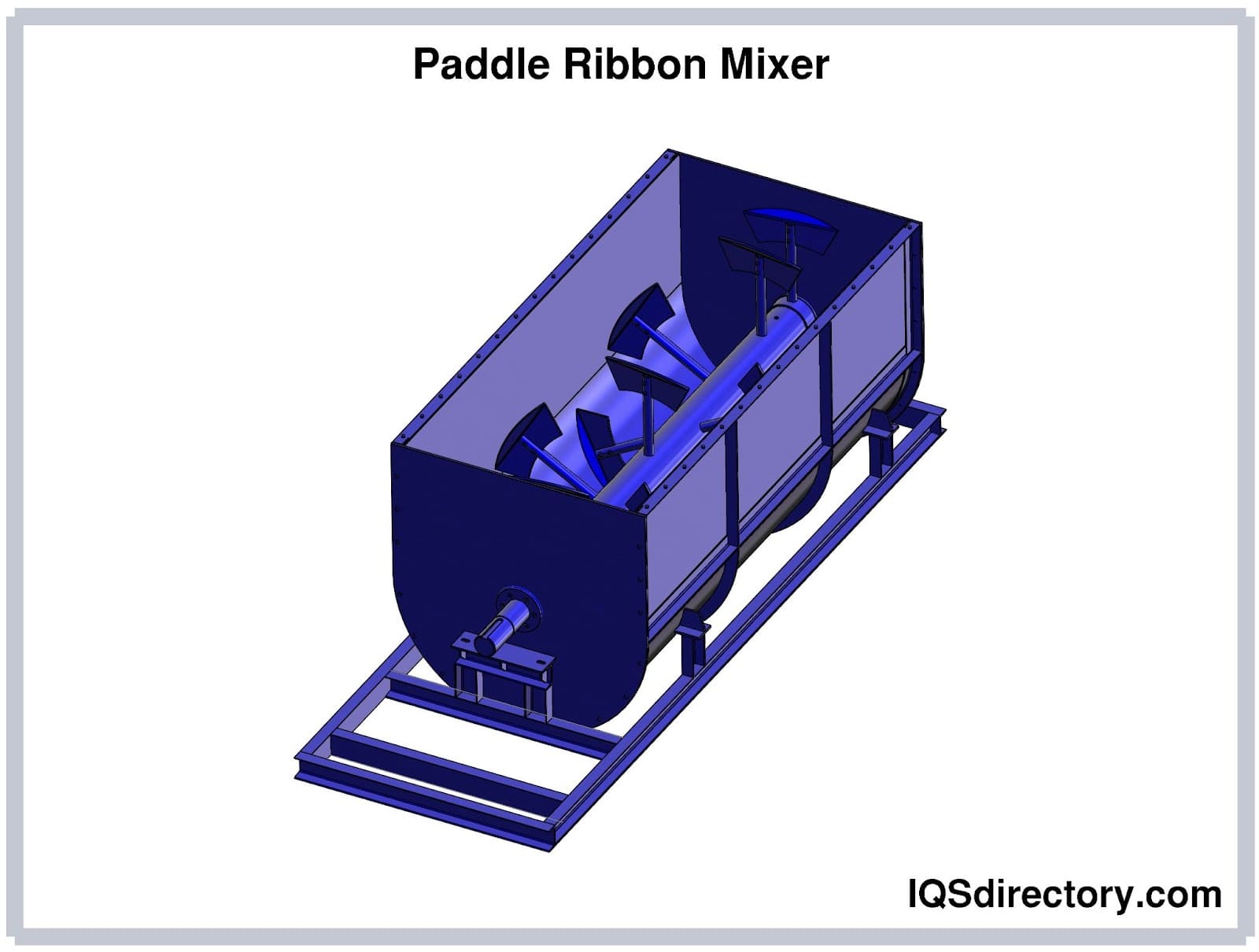

Paddle Ribbon Mixer

This type of paddle mixer combines outer paddles with inner ribbons while maintaining a counter-directional flow. The outer paddles minimize pinch points at the wall; thus, less frictional heat is introduced than a continuous outer ribbon. With a low amount of energy applied to the mix, it is ideal for fragile and heat-sensitive products.

This type of paddle mixer is a solution for a variety of applications. It ensures rapid and homogeneous blending of even the blending applications that are most difficult due to its triple action.

Continuous High Speed Paddle Mixer

This type of paddle mixer is ideal for the continuous intensive mixing of fine and cohesive powders. In addition, it offers the benefit of short residence times and accurate temperature control. This type of mixer is a horizontal paddle mixer with paddles located in a single or double helical pattern around the rotor shaft.

The typical residence time for this type of mixer is 1 to 20 seconds. The system can be used for various applications, including high-intensity mixing, fine agglomeration, coating, or continuous reaction of gasses with powders.

Due to the close contact between the material and the heated inside surface, it is capable of very high heat transfer efficiency. Depending on the requirements of the process, units can also be fitted with a cooling or heating jacket.

Applications and Uses of Paddle Mixers

Mixing-paddle mixers are utilized in:

- Mixing lime for SO2 neutralization, fly ash, municipal sludge for composting facilities, and other processes combining dry and moist feed materials

- Agglomeration-granulation of fertilizers, agricultural chemicals, carbon powders, chemical consumer products, animal feed, and flue dust from dust collectors

- Conditioning-cement or lime kiln dust, fly ash, iron oxide, foundry dust, lead fume, friction material waste, zinc oxide, copper reverts

Choosing the Right Paddle Mixer Manufacturer

To ensure you have the most beneficial outcome when purchasing a paddle mixer from a paddle mixer manufacturer, it is important to compare several companies using our directory of paddle mixer manufacturers. Each paddle mixer manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each paddle mixer business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple paddle mixer companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services