Static mixers are precision-engineered devices that serve in the continuous mixing of fluid materials with stationary components. The fluids that are mixed are usually liquid, but these mixers can also be utilized to mix gas streams, blend immiscible liquids, or disperse gas into a liquid. Read More...

Ross LPD/LLPD (Low Pressure Drop) and ISG (Interfacial Surface Generator) Static Mixers are well proven for wide ranging uses in turbulent and laminar flow mixing applications. These designs can be supplied as complete plug-in modules or as mixer inserts designed to fit an existing pipe or tubing. If you have a current need for Static Mixers, we would be happy to recommend a suitable model...

The Admixer series of sanitary static mixers and blenders is perfect for food, beverage & dairy processing. The Admixer delivers a 100% product uniformity and distribution from controlled shear and turbulence. It meets 3-A Standard #35-04 and is designed to process flow streams from 0.25 to 250+ GPM. The Admixer blends most combinations of flow, viscosity and density even from multiple incoming...

More Static Mixer Manufacturers

What is a Static Mixer?

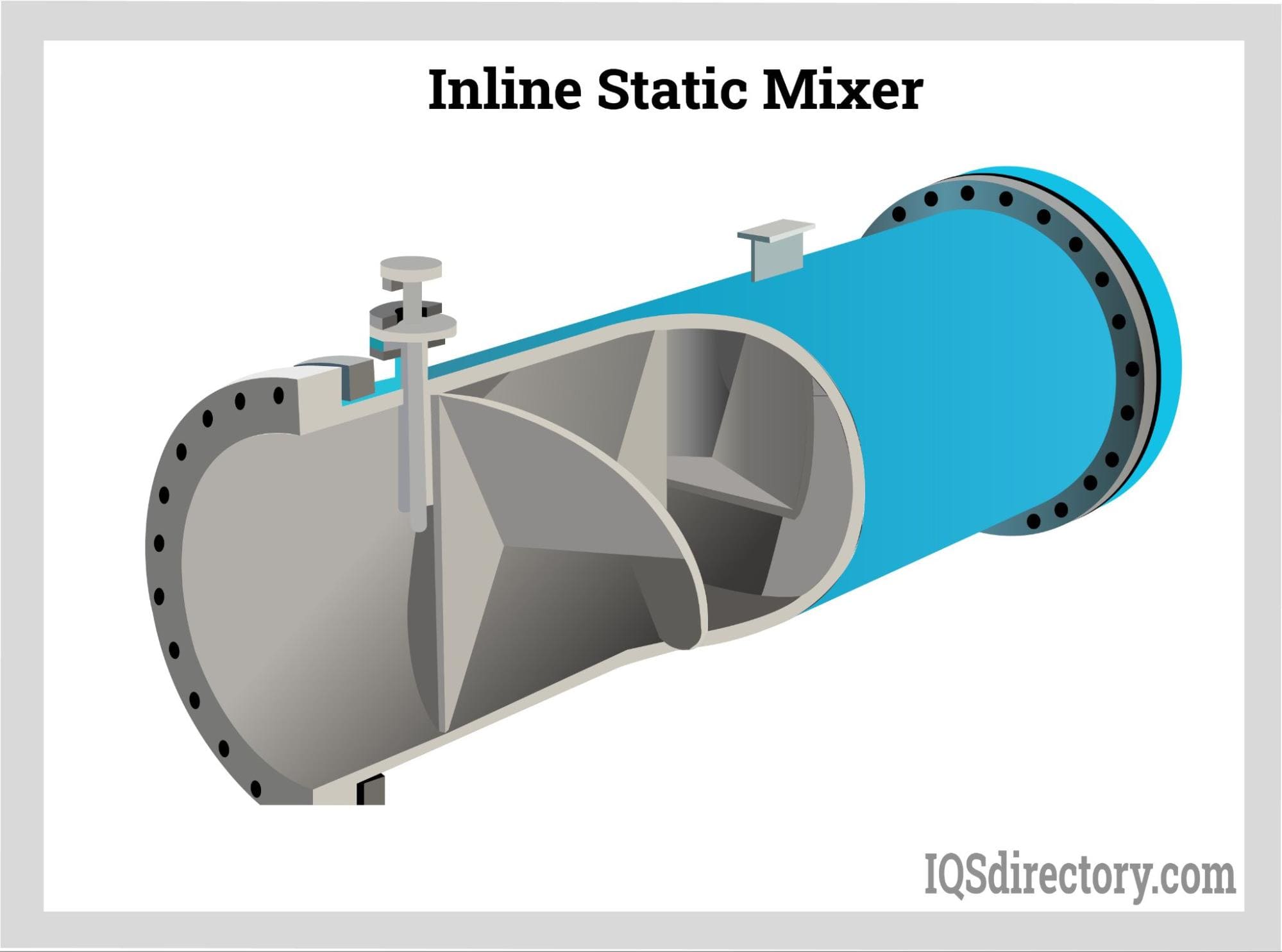

Static mixers are precision-engineered devices that serve in the continuous mixing of fluid materials with stationary components. The fluids that are mixed are usually liquid, but these mixers can also be utilized to mix gas streams, blend immiscible liquids, or disperse gas into a liquid.

The energy required comes from pressure loss as fluids flux through the static mixer. A static mixer consists of a housing pipe and mixing elements but does not contain any moving parts. Instead, the product is mixed by the flow through the mixer.

Static mixers consist of a rectangular plate twisted 180 degrees, creating a left element and a right element, depending on the twist direction. The basic length of an element is 1.5 times the length of the diameter.

How Static Mixers Function

The mixing element causes turbulence in the housing of the mixer, which will, in turn, mix the chemicals that are added either prior to the mixing or through the housing mixer’s injection port.

Within 3D of the mixer exit, the process media will be 95% mixed; this is known as CoV (Coefficient of Variation). The CoV targeted for static mixers is a coefficient of variation of 0.5 or 95% mixed at 3D from the mixer’s exit.

Static Mixer Installation

Static mixers can be flanged to fit in a pipe system. Static mixers can also come with plain ends; the customer supplies the fittings for the ends. They can also come with tri-clamp ends in the food and pharmaceutical industries.

The tri-clamp end connections mean that they can be removed from the pipeline with great ease for cleaning. Bolted flanges do not have to be removed.

Types of Static Mixers

The different types of static mixers include:

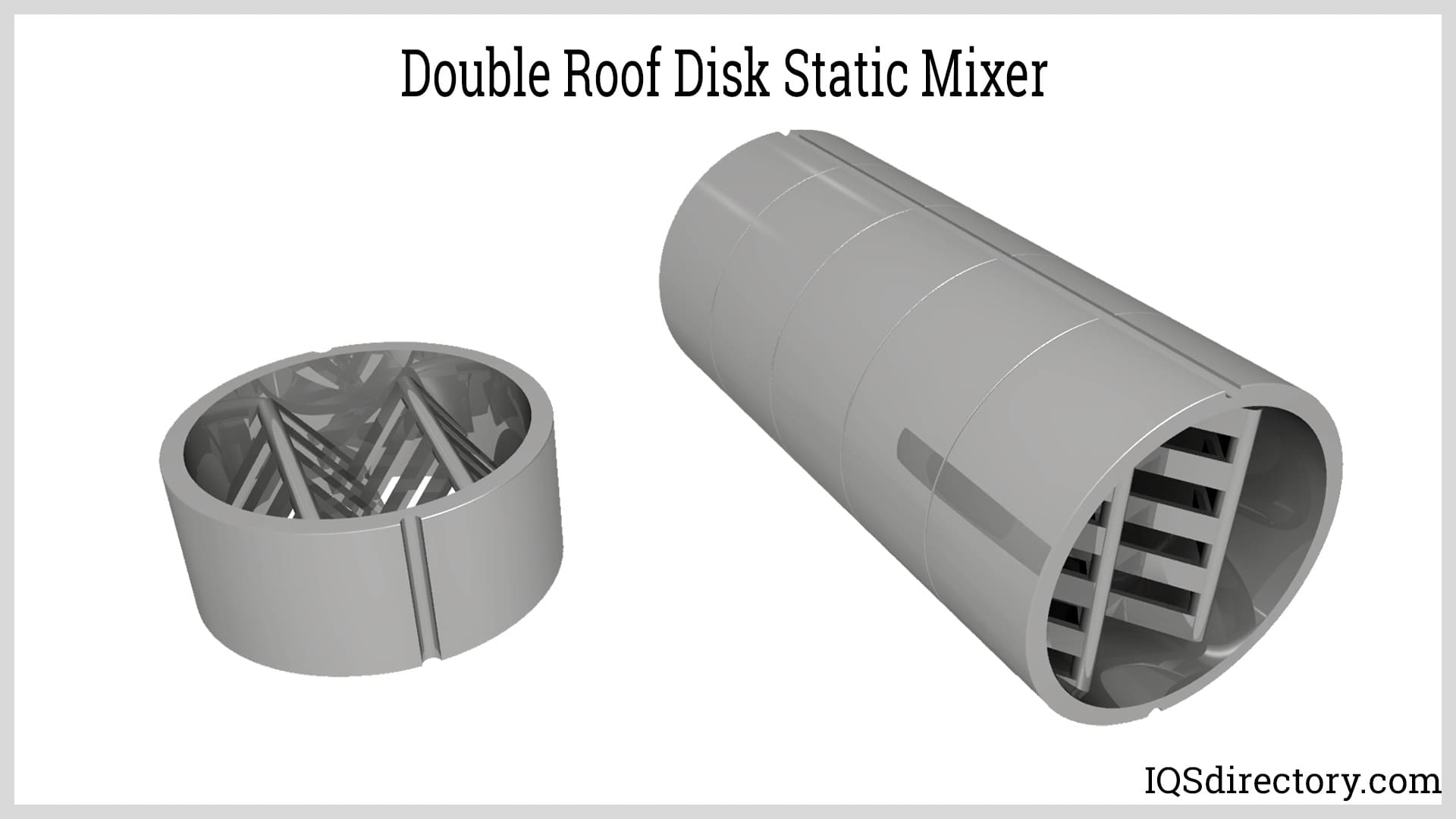

Double Roof Disk Static Mixer

This type of static mixer is utilized in the mixing, homogenization, and dispersion of viscous materials. It is a high-performance motionless mixer design capable of creating a very high degree of mixing within a very short period. It can mix materials that exhibit very large differences in volumetric and viscosity ratios.

Inclined Plate Static Mixer

This type of static mixer is utilized for the laminar flow mixing or dispersion of viscous fluids. It is also a high-performance mixer that can mix materials with extremely large differences in volumetric and viscosity ratios. It can mix thoroughly within a very short time.

Corrugated Plate Static Mixer

This type of static mixer is a high-performance and inline static mixer. It can mix liquids of low viscosity, blend gasses, disperse immiscible liquids and create gas-liquid dispersions within a short time but with an extremely high degree of accuracy.

Helical Static Mixer

This type of static mixer is cost-effective and exhibits moderate mixing performance capabilities. It is mostly used in small-diameter turbulent flow and laminar flow applications.

The mixing task is simple where its open geometric structure and low-pressure drop characteristic features are best for the specified application. Helical static mixers are available in plastic and metal construction in various configurations and sizes.

Applications and Benefits of Static Mixers

The different applications and benefits of static mixers include:

Applications of Static Mixers

- Dispersing immiscible liquids like water and crude oil in refineries for extraction applications

- Contact liquids and air for oxidation

- Food processing

- Plastic extrusion

- Polymer processing and Manufacture

- Pharmaceutical

- Media that contains high solids concentration

- Paint and lacquer/dyes

- Aromas

- Mixing catalyst

- Polyelectrolyte in wastewater

Benefits of Static Mixers

- Highly efficient mixing

- Minimal space requirement

- Ease of installation

- No need for tanks

- Low energy consumption

- Chemical savings

- No moving parts for maintenance; free operation

- No requirement for direct motive power

Choosing the Correct Static Mixer Supplier

To ensure you have the most productive outcome when purchasing a static mixer from a static mixer supplier, it is important to compare several companies using our directory of static mixer suppliers. Each static mixer supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each static mixer business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple static mixer companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services